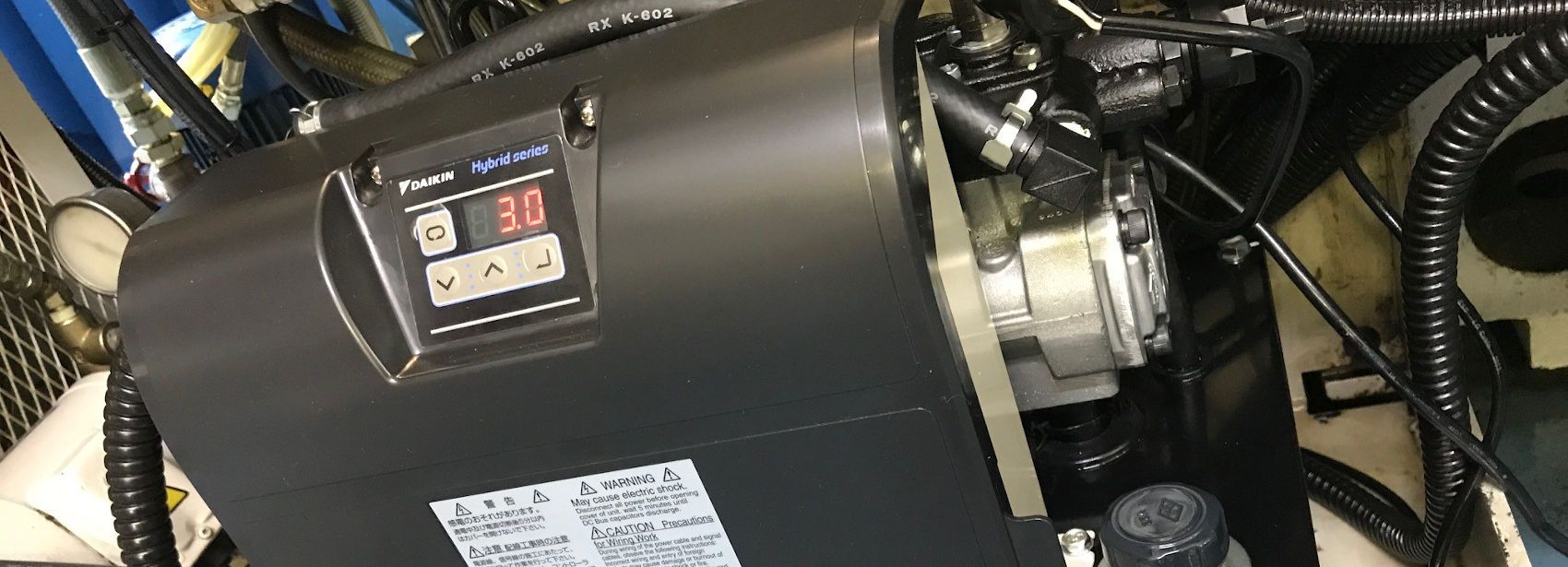

Daikin Power Packs, thanks to their IPM technology and inverter drive, are a cornerstone of efficiency and performance within the hydraulic power systems realm. Engineered for excellence, they provide a sustainable, high-quality solution for a variety of applications across numerous industries, but namely amongst industrial manufacturing. To preserve the integrity and extend the lifespan of your power pack, a structured maintenance regime is essential. This guide will walk you through the crucial steps to ensure your Daikin Power Pack operates at its peak.

Regular visual inspections are a fundamental aspect of maintenance. Checking for oil leaks, listening for unusual noises, and observing temperature fluctuations can help detect problems before they escalate. Ensure that your inspection checklist includes all these parameters to prevent any potential issues from slipping through the cracks.

Cleanliness is paramount in maintaining any hydraulic system. Dust, dirt, and other contaminants can cause significant wear and damage to the components of your Daikin Power Pack. Regular cleaning of the external surfaces, as well as the workspace around the power pack, will aid in preserving its condition and performance.

Hydraulic fluid is the lifeline of your power pack, and maintaining its quality is critical. Regularly check the fluid levels, and look out for signs of contamination or degradation. Implement a scheduled fluid analysis programme to monitor viscosity, cleanliness, and the presence of water or other contaminants that can affect the system's efficiency and reliability.

As well as completing daily checks on the Oil level, Oil temperature and quality, it is also recommended by Daikin that once every six months you perform a visual oil check to make sure the colour is not changing significantly towards a dark brown colour from it's normal yellow. If this colour is changing, it means the quality of the oil is deteriorating and it is important that you now change the hydraulic oil in your System. A full change of hydraulic oil is recommended to be carried out once every year.

Filters are integral to protecting your hydraulic system from external and internal contaminants. Following the manufacturer's recommendations for filter replacement is vital. Neglecting this aspect can lead to a build-up of contaminants, resulting in wear, inefficiency, and eventual system failure. Daikin recommend that you disassemble and clean both the oil inlet port with air breather (Filler breather) and the suction strainer once a year to maintain peak performance. This is easily achieved once these are removed by blowing with compressed air to remove any build up of material from the filters.

Proper cooling and temperature regulation are crucial for maintaining the performance of your power pack. Overheating can rapidly diminish the life of hydraulic components. Ensure that the cooling system is functioning correctly and that any heat exchangers or radiators are clear of obstructions and in good working order. You should be inspecting the fan motor of the oil cooler daily to make sure it is rotating correctly. If this fan motor stops, firstly, the oil cooler functionality declines hugely and can lead to the hydraulic oil overheating, leading to deterioration, and secondly, the main motor in the power pack (this is cooled by the fan motor) will overheat, shortening it's life.

Once every six months, It is also important to monitor and complete a visual check for clogging in the core of the cooler. Clogging can lead to the oil and components reaching unnecesarily high temperatures. It is recommended that on an annual basis to disassemble the oil cooler and clean the core, again by blowing with air or steam on the core, and cleaning the dust off of the fin and the entirety of the fan motor and it's casing with a cloth (Do not use air or steam on the fan motor for risk of contamination).

Actuators, valves, motors, and pumps are the heart of your power pack. Regular checks and timely replacement of worn components can prevent catastrophic failures. Pay attention to signs of wear, such as irregular motion or decreased performance, and consult with a professional if repairs or replacements are necessary. Hydraulic hoses require yearly inspection also, to confirm there is no signs of damage, cracks or any flaws in the material that may cause them to fail without warning.

It is also important to remember to monitor the electric wiring in the power pack for cracks or damage in the sleeving, as well as completing a six monthly check to measure the insulation resistance and confirm the earth wire of the power pack remains grounded.

Keeping detailed records of all maintenance activities provides invaluable data for understanding the health of your power pack. This historical documentation can help trace recurring issues, schedule preventative maintenance, and make informed decisions based on past occurrences and trends.

While routine maintenance can often be managed in-house, partnering with professionals for more complex inspections and repairs is recommended. Experts like those at Zeus Hydratech can assist you in diagnosing intricate issues, maintaining your Daikin Power Pack and implementing advanced solutions to ensure the longevity and performance of your hydraulic system.

By following this comprehensive guide, you’ll be able to keep your Daikin Power Pack in optimal condition, ensuring reliable operation and prolonging its service life. Regular maintenance not only protects your investment but also contributes to the seamless functioning of your broader hydraulic operations.

If you are in need of any spares or replacement parts like filters or strainers for your Daikin Power Pack, contact the sales team at Zeus Hydratech today via email (sales@zeushydratech.com) or phone +44 (0) 117 213 0042.

Daikin Power Packs are versatile and can be used in industrial, marine, aerospace, and motorsport sectors.

You can purchase many Daikin Power Packs directly from Zeus Hydratech, a leading provider of hydraulic solutions in the UK.

Daikin Power Packs work by converting mechanical power into hydraulic energy, which can be used to power various hydraulic systems.

Daikin Power Packs are designed for high performance and reliability, making them an excellent choice for various sectors including industrial manufacturing and system test rigs.

Daikin Power Packs are hydraulic power systems designed for industrial and machining sectors. They are known for their reliability and performance.

Vat Reg Number: 846644204 Company Registration Number: 5230249

© Copyright 2024 Zeus Hydratech | All Rights Reserved