The engineering marvels that are hydraulic power packs are pivotal in countless industrial processes. Daikin's Power Packs, the ECORICH (EHU) and the SUPERUNIT (SUT) are hybrid hydraulic systems integrated with technology from their Air conditioning systems to enhance efficiency. In this exploration, we will delve into the intricate mechanics of these systems and reveal why they are a preferred choice by many.

Daikin Power Packs consist of numerous essential components, namely the pump, motor and control valves, amongst various others- each serving a specific function within the system. These systems on the principle of autonomous energy-saving pressure-flow rate control. The system monitors the pressure and then supplies the required flow according to the load condition. It then holds the necessary pressure whilst operating the motor at the minimum rotating speed required, then rotating at high speed to supply the required flow when the hydraulic actuator operates. These packs also integrate an simple but effective touch control panel allowing the user to set the necessary pressure and flow rate, displaying these figures clearly on the digital screen.

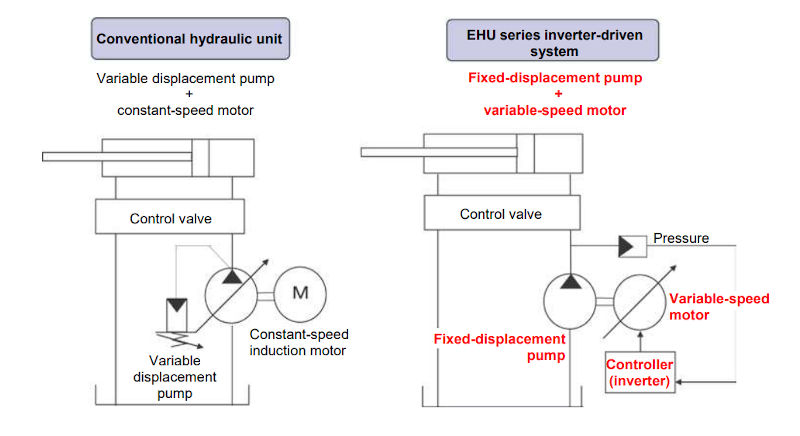

Above: A comparison between the Hydraulic circuit of a conventional hydraulic unit and that of the Daikin EHU.

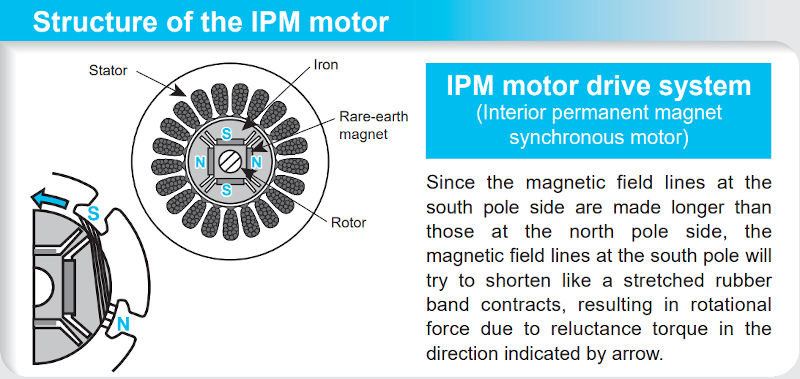

Efficiency is what sets Daikin's Power Pack apart from their competitors. Designs for both the ECORICH and SUPER UNIT's incorporate a rare-earth permanent magnet in the rotor of the motor, utilising an electromagnetic structure that acheives high torque and maximum efficiency whilst also suppressing heat generation. This high efficiency IPM technology (Interior permanent magnet) motor suprasses even IE4 class electric motors. These power packs also use a variable speed motor and fixed displacement pump, ensuring that only the required amount of power is used without waste, aiding optimal power consumtion. This efficiency is crucial in producing cost-effective, sustainable hydraulic operations and in reducing the environmental footprint of industrial processes.

The new 40 series EHU's offer the following bonuses over the 30 series:

Different sectors necessitate unique hydraulic solutions, and Daikin Power Packs are versatile enough to accommodate them. Mainly used within the industrial sector, whether it's a CNC chuck, Tail-stock, a tool rest clamp or a hydraulic press that needs powering, they provide the reliable force required for pressing, cutting, and shaping materials. Now available for order not just with a 200v, 3ph power supply but 400v, 3ph as well- you can make sure that your Daikin power pack integrates seamlessly with your machine tools and other industrial machines without the need for a transformer.

Daikin Power Pack integrates intelligent control systems to ensure razor-sharp precision in its applications. These built in systems allow for the power pack to be monitored and adjusted accordingly via the touch controls, displaying the figures for pressure and flow on the digital screen, granting operators maximum control and flexibility over pressure and flow, and ensuring that the performance is consistently at its peak.

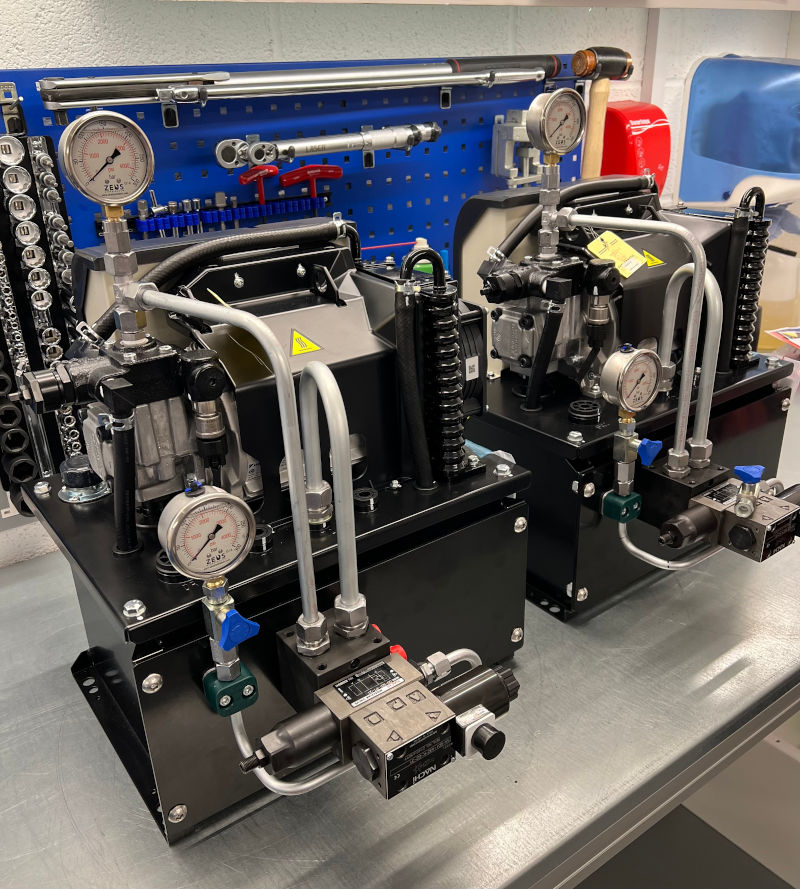

At Zeus Hydratech, we understand that one size does not fit all when it comes to hydraulic systems. That’s why we specialise in customising Daikin Power Packs to fit specific requirements. Whether it's adjusting pressure ratings & flow rates on our dedicated rig to meet a range of different OEM (Original Equipment Manufacturer) specifications, or integrating specific components, we can tailor solutions to meet the unique needs of every client.

Above: Two customised Daikin EHU hydraulic power packs, with all modifications carried out by the team at Zeus Hydratech.

Sustainability isn't solely about energy efficiency; it also involves the longevity of the system. Daikin Power Packs are built to last, making them a prudent long-term investment. With regular maintenance, these power packs can function at optimal levels for years, ensuring your processes run smoothly with minimal downtime. Read our blog all about how to maintain your power pack.

Regular maintenance of your Daikin Power Pack can be done by following the manufacturer's guidelines, or you can contact Zeus Hydratech for maintenance services & support.

Yes, Daikin Power Packs can be customised with various parameter settings to meet specific requirements of different sectors.

Yes, Zeus Hydratech offers installation services for the Daikin Power Pack.

Daikin Power Packs are known for their high performance, reliability, and versatility, making them stand out from other hydraulic power packs in the market.

Vat Reg Number: 846644204 Company Registration Number: 5230249

© Copyright 2024 Zeus Hydratech | All Rights Reserved