Hydraulic power packs, or Hydraulic power units, serve as the cornerstone for countless applications across diverse sectors. These efficient and robust systems are indispensable when it comes to delivering the power necessary to drive hydraulic systems. Making sure you have the right hydraulic power pack design for use in stress testing procedures is crucial, not just for efficiency and performance, but for the integrity and safety of the equipment and processes they support.

In the realm of engineering, stress testing represents a fundamental practice that puts systems or materials through rigorous challenges. These tests are designed to simulate extreme pressures or forces that the system or material in question may encounter in it's real world application. A well-designed and engineered hydraulic power pack is paramount in ensuring that the tests carried out provide accurate and reliable data, which can be used to gauge the durability and performance of the item under stress.

Each testing rig demands specific parameters to be met. This is why customisation lies at the heart of effective hydraulic power pack design. Zeus Hydratech specialises in manufacturing bespoke hydraulic power packs that match the unique requirements of different stress testing applications. By tailoring each system, we ensure that your testing apparatus operates at its best, offering results that are as accurate as possible.

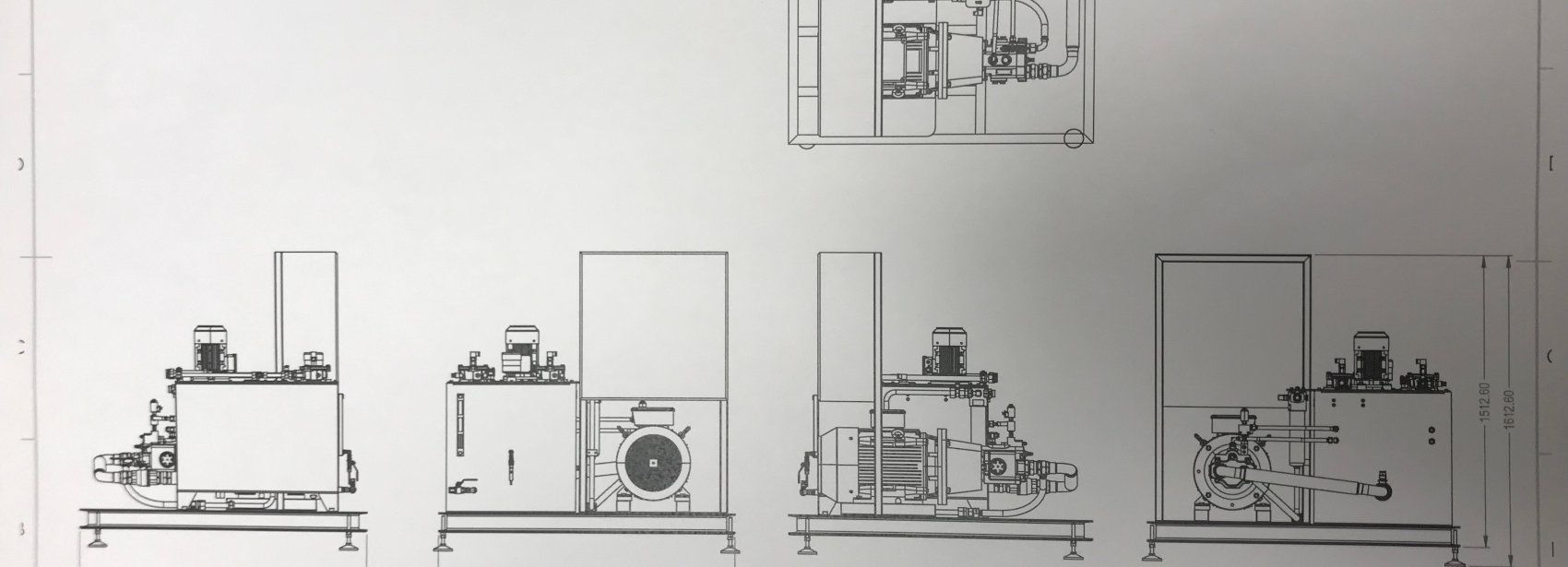

For example, Zeus Hydratech recently designed, manufactured and supplied a bespoke Hydraulic Power Pack to one of their customers in conjuction with a Electronic Control Panel, double rack Rotary Actuators and linear transducers. This Hydraulic Power Pack was supplied for the application of testing motor vehicle drive shafts, powering the actuators which in turn stressed the shaft with a variety of different directional forces to determine the level of stress they can withstand.

Above: The previously mentioned Hydraulic Power Pack for the Drive Shaft testing application.

The need for a reliable hydraulic power pack design in stress testing is present in every industry. In the aerospace sector, components must endure extreme conditions; thus, hydraulic systems used to test these components must be designed for precision and resilience to the huge forces encountered in the sky. The marine sector, industrial manufacturing and motorsport arenas equally rely on flawless hydraulic power pack designs for their rigorous testing and quality assurance processes.

Safety is undoubtedly a significant concern when conducting stress testing. A poorly designed hydraulic power pack poses risks of component failure, being unable to meet the conditions required of it or provide accurate results, which could lead to hazardous situations. Zeus Hydratech's commitment to design excellence means that every hydraulic power pack we produce is built with safety in mind, utilising industry-standard components and adhering to stringent quality control measures. This proactive approach ensures that your stress tests can be carried out safely, without compromising the system’s integrity.

Investing in top-notch hydraulic power pack design is not an option but a necessity for successful stress testing. The precision, efficiency, customisation, industry-specific applications, and utmost commitment to safety are what make Zeus Hydratech a leader in the field. By providing advanced hydraulic solutions, we enable you to carry out essential stress tests with the confidence that your hydraulic power pack is up to the task, ensuring you can make sure your systems or materials are reliable no matter the demands they face.

Yes, Zeus Hydratech can customise hydraulic power pack design to meet your specific requirements and application needs.

The design of a hydraulic power pack can greatly affect system performance. A well-designed power pack can provide the right amount of hydraulic power efficiently and reliably.

Factors considered in hydraulic power pack design include the type of hydraulic fluid, the power of the motor, the size of the reservoir, and the type and size of the pump.

Hydraulic power pack design involves creating a self-contained unit that includes a motor, a hydraulic pump, and a reservoir. It converts mechanical power into hydraulic power.

Vat Reg Number: 846644204 Company Registration Number: 5230249

© Copyright 2026 Zeus Hydratech | All Rights Reserved