The utilisation of Hydraulic Power Units in Aerospace is widespread and has been a significant contributor to this dynamic industry for decades. By offering unmatched reliability and power compared to electrical and mechanical alternatives, these systems are indispensable for a wide range of applications within the sector. In this blog post, we will explore how hydraulic power units (HPUs) are contributing to the present and future of aerospace through enhanced performance and efficiency.

Hydraulic power units are at the heart of aerospace engineering, providing the necessary force to drive the essential functions of an aircraft. From landing gear retraction and extension to controlling the rudder and flaps on the wings and tail of an aeroplane, hydraulic systems ensure these critical operations are performed smoothly and reliably. The high power-to-weight ratio of hydraulic systems makes them ideal for applications where space and weight are at a premium, which is invariably the case in aerospace design.

Continual advancements in hydraulic technology are propelling the aerospace sector into new realms of capability and efficiency. As Industry 4.0 progresses further, Modern HPUs can now be equipped with sophisticated controls that deliver precise power management, ensuring optimal performance under varying operational conditions, as well as a variety of sensors allowing the user to track factors such as temperature, pressure, flow and fluid level. These developments in control systems and monitoring allow for refined movement and higher levels of safety, which are imperative in the aerospace industry.

One of the key advantages of hydraulic power units is the capacity for customisation. Aerospace engineers can work closely with manufacturers, such as Zeus Hydratech Limited, to design HPUs that perfectly match the specific requirements of their projects. Flexible design solutions mean that hydraulic systems can be seamlessly integrated into the complex assemblies of modern aircraft, contributing to overall system efficiency and reducing the chance of mechanical failure.

The robustness of hydraulic systems also plays a crucial role in extending the lifecycle of aerospace equipment. By employing high-quality materials and meticulous manufacturing processes, hydraulic power units can withstand the extreme conditions encountered in aviation, such as temperature fluctuations and intense mechanical stresses. This durability translates into lower maintenance costs and less downtime for critical aerospace operations.

Beyond their application in actual flight operations, HPUs are instrumental in the development and testing phases of aerospace component manufacturing. Test rigs equipped with hydraulic systems simulate the conditions components will face in flight. This ability to rigorously stress-test parts, such as the gearboxes for helicopters, before they are integrated into aircraft is vital for confirming important factors such as endurance and safety, streamlining the path from design to mass production.

Real-world applications of hydraulic power units in the aerospace sector offer compelling case studies of their transformative impact. Whether in new-generation commercial airliners, military jets, helicopters or space exploration vehicles, HPUs have been central to notable successes in design, functionality, and mission accomplishment. By examining these instances, we can appreciate the extensive capabilities and adaptability of hydraulic systems within this competitive field.

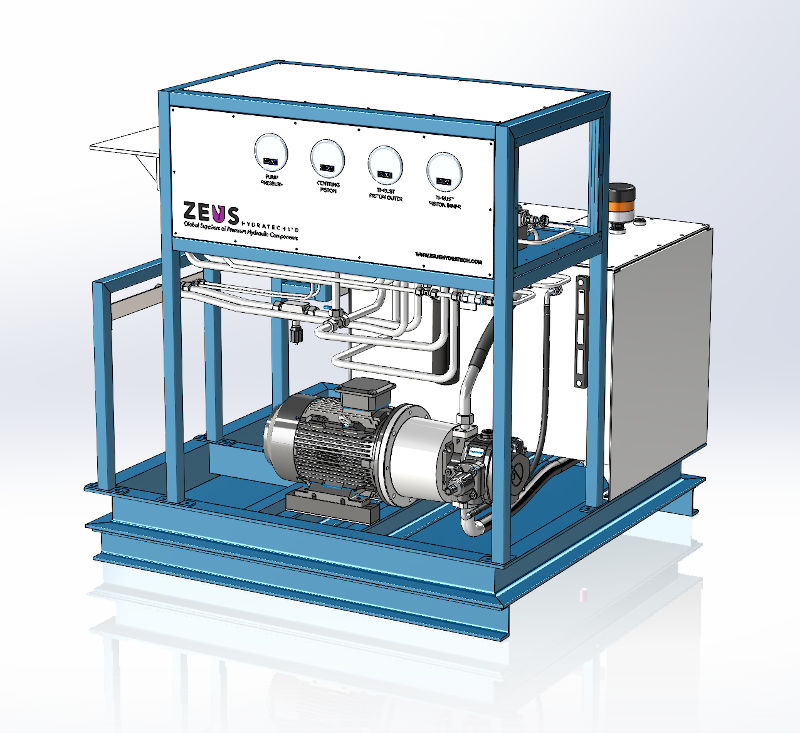

Recently, Zeus Hydratech embarked on a project comissioned by a Major Aerospace manufacturer in the South-West of the UK, to design and manufacture a Hydraulic Power Unit to replace an existing system connected to a hydraulic quenching press that had developed issues with pressure loss, jerky movement and overheating. Requiring precise control to be maintained to keep tolerances in the manufacturing consistent, this was an important project. Read more about this complex project, that was succesfully completed by Zeus Hydratech.

Above: The CAD drawing of the aforementioned Hydraulic Power Unit supplied to the UK based Aerospace manufacturer.

In essence, hydraulic power units serve a vital role within the aerospace industry, driving it toward greater heights of innovation and excellence. As the sector continues to advance, HPUs will remain a foundational technology, enabling the creation of even more sophisticated and reliable aircraft to explore the skies and beyond.

Hydraulic power units in system test rigs are used to complete stress testing or proving design concepts prior to mass production.

We cater to various sectors including industrial, marine, aerospace, and motorsport.

Zeus Hydratech provides top-quality hydraulic power units tailored to your specific needs, with a focus on reliability and efficiency.

Industrial hydraulic power units are systems that use fluid to generate power, often used in industrial manufacturing processes.

A hydraulic power unit manufacturer designs, manufactures, and installs hydraulic power pack systems used in various sectors.

Vat Reg Number: 846644204 Company Registration Number: 5230249

© Copyright 2026 Zeus Hydratech | All Rights Reserved