When diving into the realm of hydraulics, understanding the complexities of a hydraulic power pack is essential for ensuring efficiency, reliability, and performance in any high-pressure system. This comprehensive guide will navigate through the critical design considerations for these versatile components, offering insight into their role within various industrial applications.

The hydraulic power pack serves as the heartbeat of a hydraulic system, supplying the necessary power to drive machinery and equipment. At its core, a power pack is comprised of several key components that must be carefully selected and configured to meet the demands of its intended application. Let's explore the anatomy of these units:

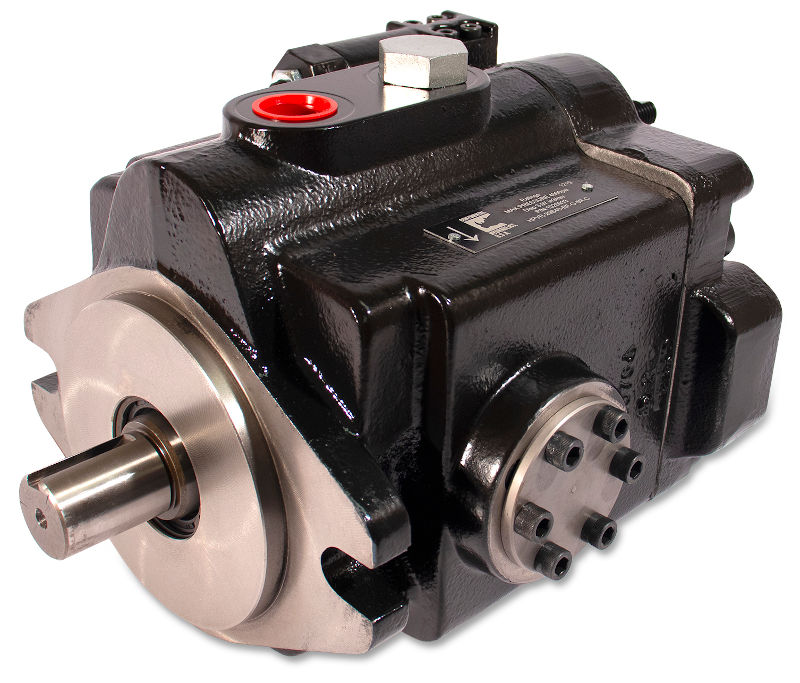

The choice of Hydraulic Pump will depend on various factors including, pressure, flow, and duration of cycle. A simple fixed displacement gear pump can be utilised for applications that require a constant flow and pressure (driving a hydraulic motor at a fixed speed for example)

Pressure compensated pumps provide a greater level of efficiency by providing pressure only when required. These pumps are generally more expensive but will give improved performance. Using a variable-displacement, pressure-compensated pump rather than a fixed-displacement pump reduces circuit horsepower requirements dramatically.

When calculating the power input to the pump, the total pump efficiency must be included. This efficiency is the product of volumetric efficiency. The average for axial piston pumps = 0.87. The formula shown on our fluid power formula page allows for an efficiency of 80%.

View our range of hydraulic pumps here.

The Electric Motor is the component that will drive the hydraulic pump and in turn, develop a flow of hydraulic oil. Electric motors provide instant torque, smooth running and quiet operation.

This must be sized specifically for the power pack application; it will be their job to provide sufficient horsepower to drive a hydraulic pump capable of delivering the required flow and pressure for the hydraulic circuit.

To calculate the size of the electric motor, we must first establish the size of the hydraulic pump to give the required flow for the system. Once we have sized the pump, we then know the power required to drive the pump and specify the correct size motor or engine.

View our range of electric motors here.

The reservoir holds excess hydraulic fluid to accommodate volume changes from: cylinder extension and contraction, temperature driven expansion and contraction, and leaks. The reservoir is also designed to aid in separation of air from the fluid and work as a heat accumulator to cover losses in the system when peak power is used.

Design engineers are always pressured to reduce the size of hydraulic reservoirs, while equipment operators always appreciate larger reservoirs. Reservoirs can also help separate dirt and other particulate from the oil, as the particulate will generally settle to the bottom of the tank.

View our range of oil reservoirs here.

A hydraulic valve is a mechanical device that regulates the flow of the hydraulic fluid in a hydraulic system. Hydraulic systems are typically high pressure systems, this means they have to be constructed from materials that can withstand these high pressures. There are multiple methods of controlling these valves, they vary between being controlled physically and mechanically with electrical actuation, hydraulics, and pneumatics.

View our range of valves here.

Selecting the correct size for a hydraulic power pack is crucial for optimal performance and longevity. Over-sized units can lead to unnecessary energy consumption and increased costs, while under-sized packs may not deliver the required power, resulting in inefficiencies and equipment stress. Determining the exact requirements of your hydraulic system, such as flow rate and pressure, will guide you in choosing an appropriately sized power pack.

The lifeblood of any hydraulic power pack is its fluid. The choice of hydraulic oil impacts the efficiency and health of the entire system, with factors such as viscosity, thermal stability, and lubrication properties playing pivotal roles. Moreover, maintaining a clean and well-filtered supply of hydraulic fluid can significantly prolong the pack's service life by preventing contamination and wear.

Excessive temperatures can impair a hydraulic power pack's performance and damage its components. Incorporating sufficient cooling systems, whether through air or water coolers, ensures that operating temperatures remain within safe limits, thus safeguarding the pack’s efficiency and the integrity of the hydraulic fluid.

In designing a hydraulic power pack, it is paramount to integrate reliable electrical controls that cater for both automation and safety. These controls can range from simple on/off switches to complex PLC systems that provide precision control over the pack's operation. Safety features such as emergency stop buttons, pressure relief valves, and thermal cut-offs also contribute to a secure working environment and prevent system damage.

Above: A Control Panel installed on a recently completed Bespoke Hydraulic Power Unit, by Zeus Hydratech.

While there are off-the-shelf hydraulic power packs available, many applications demand custom-designed systems to meet specific needs. Tailoring a power pack involves considering factors such as space constraints, environmental conditions, and the particular tasks the hydraulic system will perform. Working with an experienced manufacturer ensures that all elements, from the choice of materials to the configuration of components, are optimised for your unique application.

Regular maintenance is the key to ensuring the reliability and longevity of any hydraulic power pack. Scheduling regular inspections and following a proactive maintenance plan help to identify potential issues before they escalate, thus avoiding costly downtime. Moreover, selecting high-quality components from reputable suppliers further enhances the system's durability and performance.

Ultimately, the success of a hydraulic power pack hinges on the thoughtfulness of its design. By carefully considering the system's components, the characteristics of the hydraulic fluid, thermal management, and control mechanisms, engineers can craft a power pack that not only works efficiently but stands the test of time in demanding industrial settings.

Zeus Hydratech Limited's expertise in designing and manufacturing hydraulic power pack systems positions us perfectly to assist customers in creating solutions tailored to their specific requirements. Understanding just how to optimise each facet of a power pack, we ensure robust performance for industrial, marine, aerospace, and motorsport applications, enabling our clients to achieve their operational goals with confidence.

Vat Reg Number: 846644204 Company Registration Number: 5230249

© Copyright 2026 Zeus Hydratech | All Rights Reserved