To view our guide on how Hydraulic Pumps work, click here.

The Hydraulic Pump is the heart of the Hydraulic System, providing the flow to meet the demands of the actuators at the output end of the system.

An early choice based on system demand is that of Fixed or variable displacement. Both Vane and Piston pumps are available with a range of displacement controls linked to pressure. As well as flow and speed capability, pressure also is a vital element within the choice of a particular pump.

Each pump type has specific attributes designed for certain applications, we have categorised the available pumps below.

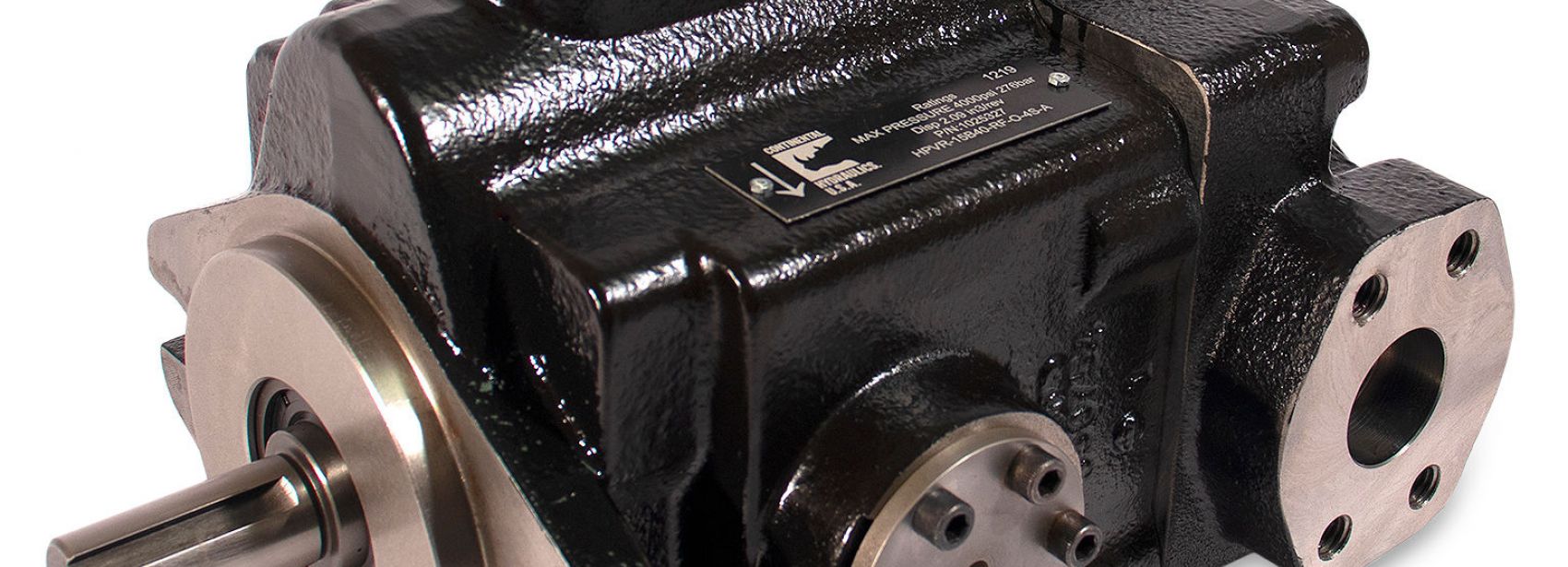

Piston pumps can have the pistons arranged in a radial or axial fashion. Radial types tend to be specialised for applications requiring very high power, while axial piston pumps are available in a wide range of displacements and pressure capabilities that make them suitable for many mobile and industrial tasks.

Axial-piston pumps consist of a set of pistons that are fitted within a cylinder block and driven by an angled swash plate powered by the input shaft. As the swash plate rotates, the pistons reciprocate in their respective cylinder block bores to provide the pumping action. Axial-piston pumps are available with the input shaft and pistons arranged coaxially, or with the input shaft mounted at an angle to the piston bores.

Bent axis pumps tend to be slightly more volumetrically efficient for technical reasons, but they also tend to be slightly larger for a given capacity and their shape can present packaging difficulties in some applications.

A unique characteristic of a piston-type pump is that the displacement can be changed simply by changing the angle of the swash plate. Any displacement between zero and maximum is easily achieved with relatively simple actuators to change the swash plate angle.

Key Details:

View our range of Hydraulic Piston Pumps here.

.jpg)

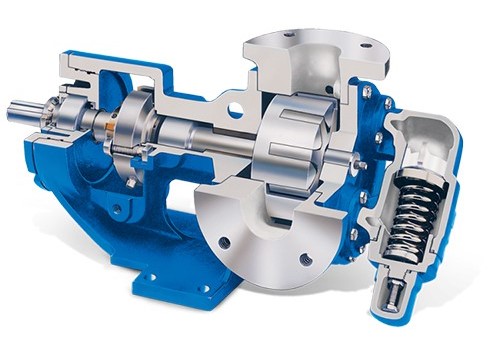

Used in both Industrial and Mobile applications, this fixed displacement pump can be very conveniently serviced (or even have its displacement altered) by simply changing the internal pumping cartridge. When carrying out this operation it is extremely important to examine the condition of the drive shaft splines and remove any wear debris from the casing if the pump before installing the new cartridge. A complete renovation of the pump still requires removal from the prime mover to change the front bearing and the shaft seal.

The vanes are pressed against the cam ring by directing the outlet pressure to the underside of each vane element. As the outlet pressure raises the vanes press harder to keep the internal leakage to a minimum. On the suction side of the pump this creates a vane tip force which is unnecessarily high (and causes wear).

More sophisticated versions of this pump limit the vane tip force by various means.

Key Details:

View our range of Hydraulic Vane Pumps here.

.jpg)

In addition to the fixed Displacement balanced vane pump, pressure compensated vane pumps provide a greater level of efficiency by providing pressure only when required. As the pump pressure rises due to the downstream resistance to flow, it will eventually generate sufficient force to move the internal compensator spool (known as cracking pressure). As the pressure rises the pump displacement will reduce until eventually it moves to a de-stroke position. At this stage it will remain slightly on stroke maintaining its own internal lubrication and leakage into the pump casing.

Key Details:

View our range of Hydraulic Vane Pumps here.

The external gear pump is the cheapest type of hydraulic pump and is very popular on systems which are constrained to have a very low build cost. Noise levels on gear pumps are generally high and efficiency is typically low – both get worse as the pressure increases however, for low pressure intermittent use, these pumps are perfectly adequate.

Key Details:

View our range of Hydraulic Gear Pumps here.

.jpg)

The internal gear pump is more expensive than the external gear pump, but is more robust and significantly quieter. There is a much smoother output (Pressure Ripple) and they can run at higher pressures without the excessive noise levels.

Key Details:

View our range of Hydraulic Gear Pumps here.

Vat Reg Number: 846644204 Company Registration Number: 5230249

© Copyright 2026 Zeus Hydratech | All Rights Reserved