Discovering the right hydraulic pump for your power pack unit is crucial for ensuring peak performance and reliability. At Zeus Hydratech, our expertise lies in designing and installing hydraulic power pack systems that meet the rigorous demands of system test rigs and industrial manufacturing. In this comprehensive guide, we delve into the crucial aspects of selecting the appropriate hydraulic pump for your power pack needs.

The heart of any hydraulic power pack is the pump. This vital component converts mechanical energy into hydraulic energy, emitting a flow of oil that powers the entire system. The type and size of the pump must be well-matched to your system's specifications to achieve optimal efficiency and performance.

Choosing the correct hydraulic pump hinges on understanding your power pack's operational parameters, such as pressure, flow rate, and power requirements. Pumps come in various types, like gear, vane, and piston pumps, each suitable for specific applications. For high-power applications, piston pumps are ideal, while gear and vane pumps may be more suitable for lower pressure demands.

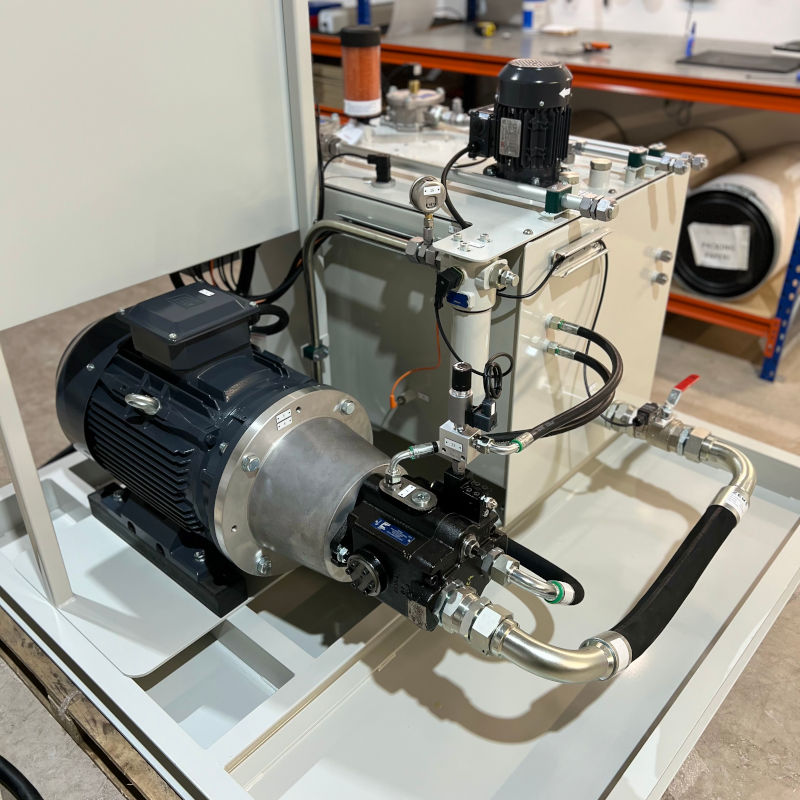

Above: A recently installed Continental Hydraulics axial piston pump installed on a Bespoke Power pack, designed and manufactured by Zeus Hydratech.

Efficiency is the cornerstone of effective hydraulic systems. A pump that is well-tuned to your power pack will not only save energy but also reduce wear and tear on the system, leading to a longer service life and fewer maintenance issues.

A hydraulic pump's durability is as important as its efficiency. High-quality materials and robust construction ensure that the pump withstands the demanding environments typical of the marine, aerospace, and motorsport sectors. Superior materials used in the construction of pumps provide resistance to wear and corrosion, ensuring the long-term operation of your hydraulic power unit.

At Zeus Hydratech, we specialise in custom hydraulic power packs, ensuring that each component, including the pump, is tailored to meet the unique requirements of our clients. Our custom solutions provide a significant advantage in terms of performance, where a one-size-fits-all pump may not suffice.

Maintaining your hydraulic pump is critical to your power pack's continued health and efficiency. Regular inspections and maintenance help identify potential issues before they escalate into costly repairs or system downtime. When you entrust the maintenance of your hydraulic unit to Zeus Hydratech's professionals, you can be sure that your pump will always function at peak efficiency.

Choosing the correct hydraulic pump for your power pack is not just about specifications; it's about understanding the nuances of your hydraulic system and its applications. With Zeus Hydratech as your partner, you can rest assured that your hydraulic power unit is equipped with the perfect pump designed for efficiency, durability, and peak performance. Contact us today to learn more about our comprehensive hydraulic solutions.

Optimal Hydraulic Power Solutions for Industrial Applications

Power Pack Pumps: Maximise Efficiency in Hydraulic Systems

Exploring the Versatility of Small Hydraulic Power Units

The Comprehensive Guide to Hydraulic Pump Power Units

The Indispensable Role of Power Unit Hydraulic Pumps Across Industries

To extend the life of a power pack pump, regular maintenance, using appropriate hydraulic fluids, ensuring clean fluid with proper filtration, avoiding overloading the system, and following operational best practices are all crucial preventive measures.

Hydraulic power pack pumps are widely used across various industries, including industrial manufacturing, marine, aerospace, motorsport, and more, particularly where precise control and high power density are required in actuation and motion control systems.

While some hydraulic power pack pumps are designed to be versatile with different types of hydraulic fluids, others may be more specific in their requirements. It is critical to confirm compatibility to prevent damage to the pump and the overall system.

The servicing interval for a hydraulic pump in a power pack unit varies depending on the manufacturer’s recommendations, system usage, and operational conditions. Typically, a regular annual service schedule is essential for ensuring longevity and reliability of the pump.

Common types of hydraulic pumps used in power pack units include gear pumps, piston pumps, and vane pumps. Each type has its own advantages and is suitable for different pressures, flow rates, and application requirements.

The efficiency of a hydraulic power pack pump directly impacts the system's performance. Higher efficiency leads to better energy conversion, reduced heat generation, and overall reliable operation of the hydraulic system. Conversely, a low-efficiency pump can lead to energy losses and potential system failures.

Signs that a hydraulic pump requires maintenance include unusual noises, vibration, decreased performance, overheating, leakage, and an overall drop in system efficiency. Regular inspections can help identify these issues early on.

A power pack pump can often be repaired if the damage isn't extensive. However, for cases involving severe wear or internal damage, replacement might be the more cost-effective and reliable option. It's advisable to conduct a thorough assessment to decide the best course of action.

The selection of the right hydraulic pump for a power pack unit depends on several parameters, such as required pressure, flow rate, system efficiency, and compatibility with the hydraulic fluid. It's also important to consider the operational environment, expected workload, and specific application requirements.

The hydraulic power pack pump is a critical component of a hydraulic system that generates the flow of hydraulic fluid needed to create pressure. It converts mechanical power into hydraulic energy, facilitating the movement of fluids from the reservoir to other components within the system, thereby enabling the operation of actuators and motors.

Vat Reg Number: 846644204 Company Registration Number: 5230249

© Copyright 2026 Zeus Hydratech | All Rights Reserved